Discover the Original

The POGO® Flexible Tooling System is a turnkey, automated, universal holding fixture used to rigidly hold contoured panels made of metal and/or composites for a variety of manufacturing operations (i.e., trimming, drilling, waterjet cutting, inspection, laser scribing, laser cutting and assembly).

This programmable system offers the benefit of eliminating the need for dedicated tooling fixtures and their associated costs (design, fabrication, storage, maintenance, setup, transport, etc.), as well as improving part quality and production throughput.

The POGO® system is typically integrated with a CNC machine tool or robot, creating a completely integrated, flexible manufacturing cell.

FTS’s flexible tooling systems have proven themselves over the past 25 years as a superior, agile manufacturing solution by reducing tooling set-up times, storage costs, and maintenance costs while improving part quality and production throughput.

Read more about our history and technology below.

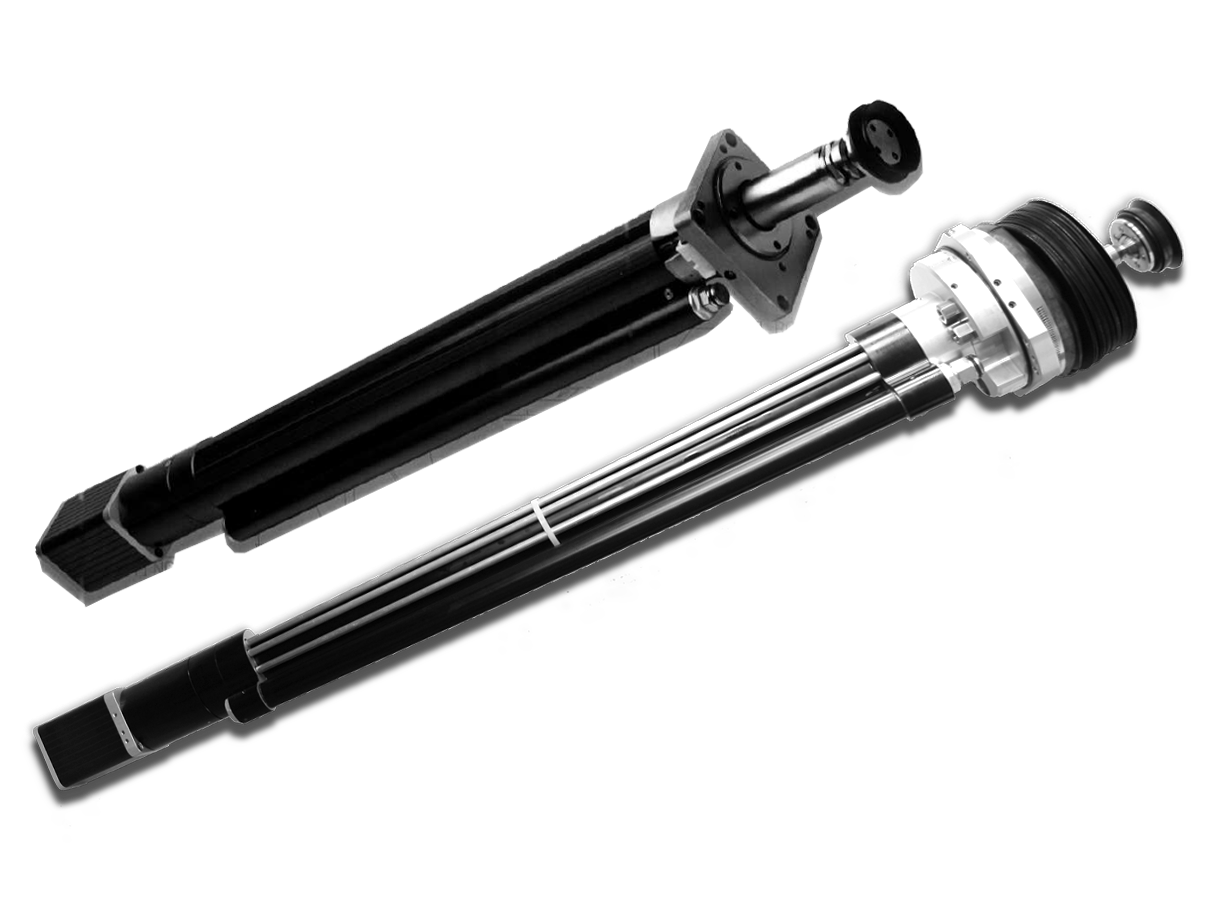

System Components

Each POGO® flexible tooling system consists of the following primary components:

- POGO actuators

- Vacuum end effectors

- System controller and software

- Modular table structure

Key Features

- POGO® actuators with positioning accuracy of ±0.003″

- Simple, hybrid pneumatic and smart actuator technology

- Quick programming for rapid response to engineering and production changes

- Modular structure facilitating custom system configurations and system expandability

- Seamless interface with machine control for fully integrated, automated manufacturing center

- CAD data conversion to part manufacturing with minimum effort

- Production-proven durability at 98% uptime

Benefits

- Significant increase in part accuracy and quality

- Reduction in inspection requirements

- Considerable reduction in setup time

- Elimination of dedicated tooling and associated storage and floor space

- Reduction in material inventories

- Scalable, flexible and universal for current and future requirements