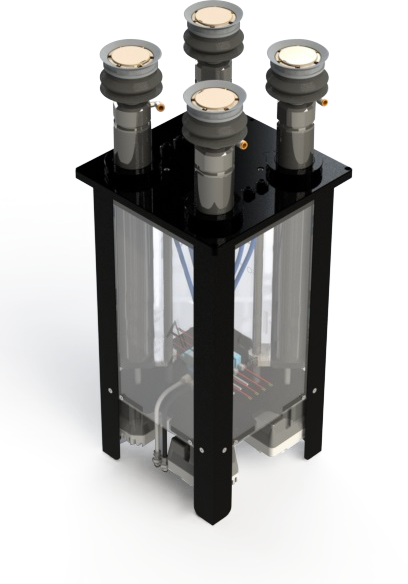

Introducing the

POGO-POD®

4 actuators per POGO-Pod®,

capable of 50 lbs of suction each

Unlimited program capabilities

within work envelope

Simple to operate

and maintain

Repositions in 30 seconds

so you can work on

different parts with zero hassle

Repeatable actuator

positioning to within .003”

Priced at a level that

surprises our customers

(in a good way)

Easily holds difficult,

contoured surfaces

Cycle life of our systems

tested to 20 years and still

running like new.

Click on one of the dots for more details.

Here's what the Amazing

Offers for your business:

- Precise and repeatable positioning to within .003″ tolerance.

- Program set up in less than 3-5 minutes for typical parts.

- Tested to 100,000 moves (20 years of heavy use).

- Real time monitoring of position and vacuum while parts are machined.

- Free floating heads allow the end effector to conform to the part surface.

- Quick change end effectors can be replaced with an assortment of styles.

- 50lbs of pull-down force per end effector

- Plug and play functionality when replacing a pod of actuators.

- Easy to use PC-based, graphical user interface, that provides in-depth control, feedback and diagnostic options.

- Up to 12″ stroke for dry environments.

FTS’s flexible tooling systems have proven themselves over the past 25 years as a superior, agile manufacturing solution by reducing tooling set-up times, storage costs, and maintenance costs while improving part quality and production throughput.

Read more about our history and technology below.

The POGO-Pod® allows you to manufacture like never before

The POGO-Pod® allows you to manufacture like never before

The POGO-Pod® is a fully assembled and operating unit. Our design makes the pod easy to operate so that you’re never left wondering. Once installed, the pod is capable of working hard for decades (we haven’t had a single machine break down in 25 years…). We’ve kept the price low to give small manufacturers and shop owners the chance to reap the benefits of this revolutionary tech.

The POGO-Pod® is designed to work in dry environments, and handle constant metal and composites dust from drilling. The POGO-Pod® comes with an integrated computer setup. The pod’s actuators move individually, and can be programmed to fit any piece and hold it firmly with strong vacuum suction. Once a piece is in the computer’s memory, you can simply press a button and the POGO-Pods® will move to that exact position. If you stop making that specific piece, the pods can adapt to any other piece and continue to save you time and money. The magic of the POGO-Pod® is in helping manufacturers and shop owners speed up their process and make parts more accurately than ever.